Process Technology - Distributed by CDI Equipment Division

Distributed by:

Equipment Overview | Filter Pump Industries / Penguin Pump | Process Technology

Process Technology's industrial products include electric immersion heaters, heat exchangers and temperature control packages. These products are designed specifically for heating and cooling of chemistry in wet process manufacturing environments. Industries served include electroplating, anodizing, printed circuit board, cleaning technologies, pharmaceutical, food, and biomedical. In addition to our standard products many custom products engineered specifically for your application are available.

Below are descriptions of our products and corresponding links, accessories, troubleshooting guides, and technical data. Please don't hesitate to contact us if you need further assistance.

SmartOne® Electric Immersion Heaters

Process Technology proudly introduces the latest in innovative heating technology - the SmartOne® self-limiting PTC electric immersion heater. With this technology, thermal overtemperature protectors are no longer required to ensure safe operation. SmartOne® heaters are more dependable with extended service life and will not burn out in air, scale or sludge like traditional resistance heaters. As the trusted industry leader for over 35 years, Process Technology continues its precedent-setting tradition of providing the highest quality wet process heating and cooling equipment. SmartOne® - the new international standard in process heating. PTC Element Technology SmartOne® heaters utilize Positive Temperature Coefficient (PTC) semiconductors as the heating element. Unlike traditional heating elements, they are SELF-LIMITING. As PTC elements heat up, their resistance to electrical current increases. You may already be familiar with PTC technology as it is used in hair dryers, curling irons, and car seat heaters.

Introducing the SmartOne® line of PTC (positive temperature coefficient) electric immersion heaters. With this technology, thermal over-temperature protectors are no longer required to ensure safe operation. PTC heaters are more dependable with extended service life and will not burn out in air like traditional resistance heaters.

Electric Immersion Heaters

Process Technology electric immersion heaters are designed for the demands of corrosive chemical heating. Open tank, screw plug and flange configurations are available. A wide variety of sheath materials ensure long life regardless of the chemistry. Materials include: fluoropolymer, quartz, titanium, 316 stainless steel, 304 stainless steel and plain steel. Sizes as small as 100 watts for laboratory environments and as large as 54,000 watts (flange heater up to 270,000 watts) for industrial applications are available. Many standard configurations are available from stock. Quick lead times are available for custom configured heaters. (Manufacturing lead times can be as short as two or three days.) Heaters are UL, CSA and CE.

Compatible with virtually any chemistry. Sizes up to 27 kW. Large variety of standard and customer configurations for over the side and bottom installations.

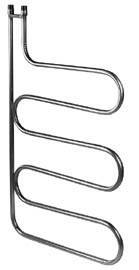

- HX Series Spiral Fluoropolymer (PTFE) heaters

- HXL Series Spiral L-Shaped Fluoropolymer (PTFE) heaters

- HXF Series Low Profile Fluoropolymer (PTFE)heaters

- HXFL Series Low Profile L-Shaped Fluoropolymer (PTFE) heaters

- HXO Series Fluoropolymer (PTFE) heaters

- 3HXO Series Three Element Fluoropolymer (PTFE) heaters

- 3HXOL Series Three Element L-Shaped Fluoropolymer (PTFE) heaters

- 3HX Series Three Element Fluoropolymer (PTFE)heaters

- 6HX Series Six Element Fluoropolymer (PTFE)heaters

- 9HX Series Nine Element Fluoropolymer (PTFE)heaters

- HXRL Series Flexible Riser Low Profile Fluoropolymer (PTFE) heaters

- HXOL Series Flexible Riser Fluoropolymer (PTFE) heaters

- HXSL Series Flexible Riser Fluoropolymer (PTFE)heaters

Variety of materials to match your application (titanium, 316 stainless, 304 stainless and plain steel). Sizes up to 54 kW. Standard and custom configurations for over the side and bottom installations.

- 3HS Series Three Element Stainless Steel heaters

- 6HS Series Six Element Stainless Steel heaters

- 9HS Series Nine Element Stainless Steel heaters

- P, F, S & T Series Metal heaters(Two inch over-the-side)

- 3P, 3F, 3S & 3T Series Metal heaters

- D Series Derated Metal heaters

- D3 Series Derated Triple Metal heaters

- L Series L-Shaped Metal heaters

- 3L Series Triple L-Shaped Metal heaters

- DL Series Derated L-Shaped Metal heaters

- D3L Series Derated Triple L-Shaped Metal heaters

- 3LV Series Vertical Stack, Triple L-Shaped Metal heaters

- FR Option Flexible Riser Option for L-Shaped Metal heaters

- Deep Tank Series Deep Tank Metal heaters

- 3V Series Deep Tank Triple Metal heaters

- DAS Series Phosphate heaters

- B Series Small Tank Metal heaters

- V Series Varipower heaters

Ideal for most acidic chemistries. Metal grounded quartz sheathed heaters up to 30 kW. Polypropylene guards standard.

Unique or difficult applications are our specialty. Configurations available include: lab heaters, flexible riser heaters, phosphate heaters, deep tank heaters, VaripowerTM heaters, EasyPlugTM heaters, etc.

Wide variety of heater types and features to fit virtually any application. Stainless, titanium, fluoropolymer and other materials. Sizes from 2" screw plug to 14" flanged.

- FT, ST and TT Series 2" Tubular Screwplug heaters

- 2T Series 2" Stainless Steel Screwplug heaters

- T2T Series 2" Titanium Screwplug heaters

- 5T Series 2-1/2" Stainless Steel Screwplug heaters

- T5T Series 2-1/2" Titanium Screwplug heaters

- TB Series Small Tank Screw Plug heaters

- HXT Series Fluoropolymer (PTFE) Screw Plug heaters

- FL Series Flanged heaters

- FLX Series 3" 150 LB. Style Fluoropolymer (PTFE) Flanged heaters

Coil and Heat Exchangers

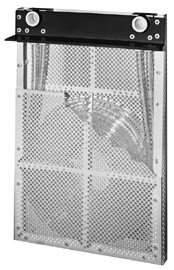

Process Technology heat exchangers and heating/cooling coils are designed for the demands of corrosive chemical heating. A wide variety of standard and custom configurations are available. Materials of construction include: fluoropolymer, titanium, 316 stainless steel, plain steel, and several exotic metals such as Zirconium. Most of our heat exchangers are open tank designs, however, we also have some inline designs such as stainless steel spiral plate units. Excellent engineering and design assistance is available upon request.

Heat exchangers designed and built to your specific application, including simple "U" coils, single and multi bank grid coils, helical coils, serpentine coils, standard and custom designs. Wide variety of materials available.

Excellent chemical compatibility. Rugged construction with perforated guards. Variety of sizes and configurations available.

Engineered specifically to your needs. Spiral plate, tube-in-tube and other designs available. Variety of materials of construction.

Temperature Controls and Accessories

Process Technology offers an extensive assortment of cataloged and custom temperature control systems for precise control of our heaters and heat exchangers. From simple control packages to complex central control stations, our team of engineers can design a control specifically to your application requirements. All controls are UL/CSA, with CE configured controls available upon request. Styles include digital display, non-indicating, on/off, and PID. Switch gear for electrical loads of up to 150 amps are available.

Sophisticated digital to simple non-indicating controls. Combination controls up to 150 amp capacity. Custom designed central control stations.

- ProTouch - HMI Series Digital Combo Controls

- NR Series Non-Indicating Thermostats

- NR Combo Series Non-Indicating Combination Controls

- DE Series 1/8 DIN Digital Thermostats

- DE Combo Series 1/8 DIN Digital Combination Controls

- DQ Series 1/4 DIN Digital Thermostats

- DQ Combo Series 1/4 DIN Digital Combination Controls

- DSL Series 1/16 DIN Digital Thermostats

- DSL Combo Series 1/16 DIN Digital Combination Controls

- DLC Series Low Cost Digital Thermostats

- DLC Combo Series Low Cost Digital Combination Controls

Conductivity and capacitive style controls for the ultimate in reliability. Multi-level controls available. Can be packaged with temperature controls.

Accessories

Process Technology offers many accessories products to assist in the proper installation and operation of our primary heater, heat exchanger and temperature control product lines.

Troubleshooting Guides / Technical data

- Immersion Heater Solution Guide

- Electric Heater Sizing

- Electric Heater Installation and Maintenance

- Electric Heater Specifications

- Inline Water Heater specifications

- Metal Heat Exchanger Sizing

- Metal Heat Exchanger Installation and Maintenance

- Sizing Information for Fluoropolymer Heat Exchangers

- Fluoropolymer Heat Exchanger Installation

- Heat Exchanger Specifications